Industrial Gaskets

Gasket is a packing designed for inclusion between rigid mating parts in essentially stationary relationship to prevent leakage. They are found in flange joints, machine and process plant assemblies. Gaskets are produced in various shapes, sizes, ratings and designs out of different materials for the medium to be contained.

Gaskets are categorized as Metallic, Semi-Metallic and Non-Metallic (Soft) gaskets and each serves a different and specialized purposes. Our gaskets are made according to ASME, DIN, JPI, JIS, BS and API standards.

Gasket Types

Camprofile or Kammprofile Gaskets are also known as Grooved Gaskets due to its physical appearance where a solid corrugated core is covered by a flexible layer of graphite, Teflon® or other materials. This gasket type provides an extremely tight seal and is known for their long-term reliability hence can be normally found among older seals or flanges.

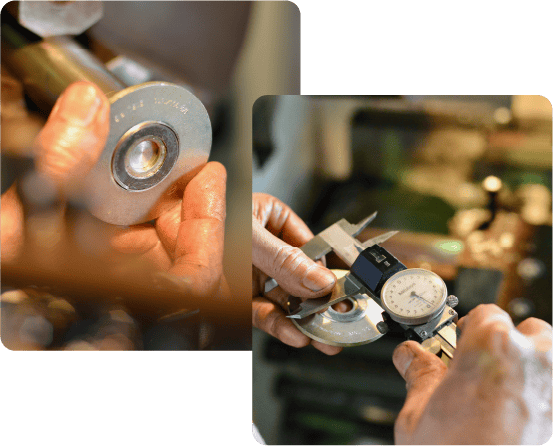

PTT also manufactures heat exchanger gaskets like metal jacketed gaskets, & camprofile. Camprofile gasket is becoming more & more popular in process plants nowadays. Traditionally, grooving of metal grooved gasket is done by large lathe machine. Today, with our special designed machine, we can produce camprofile gaskets up to 3000 mm in diameter at a much reduced production time.

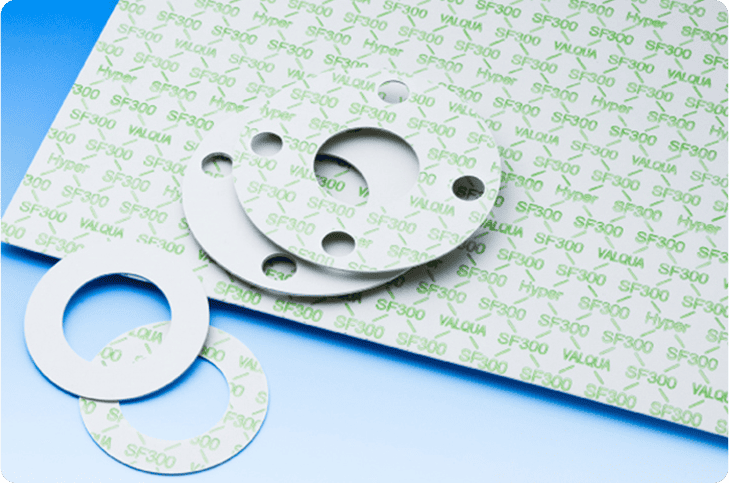

Stands for Compressed Non-Asbestos Fiber. This is categorized under non-metallic (soft) gaskets; this type of gasket is also very common. This is a substitute to Asbestos based material, minus the health hazard and is safe for both handling and disposals. Typically produced in sheet form and shapes will be cut-out according to the desired dimensions.

PTFE is Teflon® and like graphite, it is an excellent sealing material and is relatively economical.

This type of gaskets offers a wide range of applications and the ease of both handling and cutting and is often conomical to produce.

We source our CNAF and PTFE gasket sheets from reputable companies such as Valqua (Japan) and Klinger (UK).

This gasket usually made from soft metal and rather simple to fabricate and is very economical where the only material needed for producing this type of gasket is rolled metal sheets or metal strips. With the aid of our latest laser cutting machine the metal sheets will be laser-cut to certain dimensions or is cut into segments and to be weld-joint for a larger diameter gasket.

Commonly used in heat exchangers. These gaskets are constructed with filler enveloped partially or fully by metal sheets. Among the material used for fillers are:

- Non – Asbestos

- Flexible Graphite

- Teflon

- Ceramic

Metal jacketed gaskets provides the best of both worlds, combining temperature resisting property of a metal jacket and sealing property of a soft filler, this type of gaskets are easy to fabricate and is also considered economical and suitable for irregular surface and flanges faces.

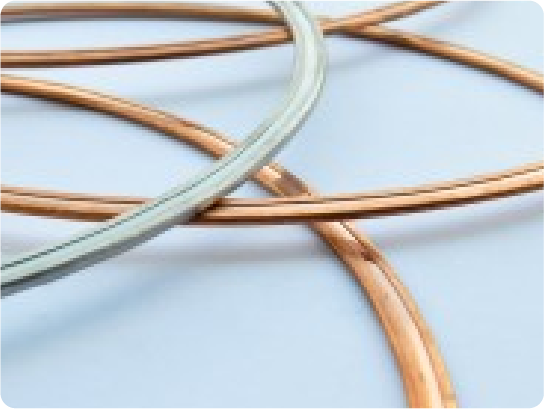

SWG Gaskets are widely used in the petrochemical, Oil and Gas industries and consists of a metal ring, graphite filler and steel strips that overlaps the filler and held together with a V-Shaped groove. SPW Gaskets are known for their superior sealing performance and is applicable for a wide range of joints and flange faces.

With our latest machine we are able to produce spiral wound gaskets to the finest quality and exacting standards and gaskets with superior sealing compatibility. We can make non standard SWGs sizes from 500 mm up to 4000 mm with thickness of the most common 4.5 as well as 6.5 & 7.2 mm.

Types of Spiral Wound gaskets are:

There are a few variations to these as well, depending on the desired application, some would be with or without the inner-ring and some would have ribs which are to suit Heat Exchangers. We have standard sizes in stock as well, wrapped and ready to be delivered.

Gasket 101

At PTT Corp, we offer a wide range of high-quality gaskets designed for various industrial applications. Our gaskets provide reliable seals to prevent leaks and ensure safety in Oil & Gas, Petrochemical, and other sectors. With top-notch materials and precision manufacturing, we deliver durable and efficient solutions.

Gasket Types

| Types of Gasket | Piping | Heat Exchanges | Valves | Tower / Tanks / Reactors | Pumps |

|---|---|---|---|---|---|

| CNAF Sheet | YYY | YYY | YYY | YYY | YYY |

| Expanded graphite sheet | YY | Y | YY | YY | YY |

| PTFE Solid Gasket | YYY | YY | YY | YYY | YY |

| PTFE Gasket with Filler | YYY | YY | YYY | YYY | YY |

| Spiral Wound Gasket | YYY | YYY | YYY | YY | YYY |

| Camprofile Gasket | YY | YYY | Y | YY | Y |

| Metal Jacketed Gasket | YY | YY | YY | YY | Y |

| Metallic Flat Gasket | Y | YY | Y | YY | Y |

| Serrated Gasket | Y | YY | Y | YY | Y |

| Ring Joint Gasket | YYY | Y | YYY | YYY | Y |

Symbols:

YYY Used very Often

YY Used Often

Y Depending on the conditions

| Metal | Temperatures up to 1093.3°C, Pressure is virtually unlimited and the resistance to chemical is also considered high |

| Teflon | Temperatures up to 316°C, Mild to aggressive chemicals |

| Non-Asbestos | Temperatures up to 454°C, Mild chemicals |

| Rubber / PVC Materials | Temperatures up to 204°C, pressures up to 10.3 bar, mild chemicals |

| Carbon / Graphite | Temperatures up to 550°C, Aggressive chemicals |

| *References made based on Valqua handbook, Nippon Valqua Industries, Ltd. (PTT Corp is a distributor of Valqua products) | |

Gasket Sheets

KLINGERSIL C-4509 – Carbon Fibre with NBR with expanded metal insert

C-4509 is an expanded steel reinforced version of C-4500 which increases the compressive strength and in turn the maximum pressure capability. The increased stability provided by the reinforcement also allows this material to be used for increased temperatures with greater resistance to thermal degradation.

Application: A wide range of media including oils, hydrocarbons, alkalis, steam where a high seal is required. Premium high pressure gasket able to withstand high thermal and mechanical loads. Outstanding resistance to alkaline media and steam.

KLINGERSIL C-4400

High quality non-Asbestos grade based on Aramid fibre with Nitrile rubber binder. A general purpose material for many industrial sealing applications

Thickness: 0.25, 0.4, 0.5, 0.75, 1.0, 1.5, 2.0, 2.5, 3.0 mm

Dimension: 2000 x 1500, 4000 x 1500, 1500 x 1000 mm

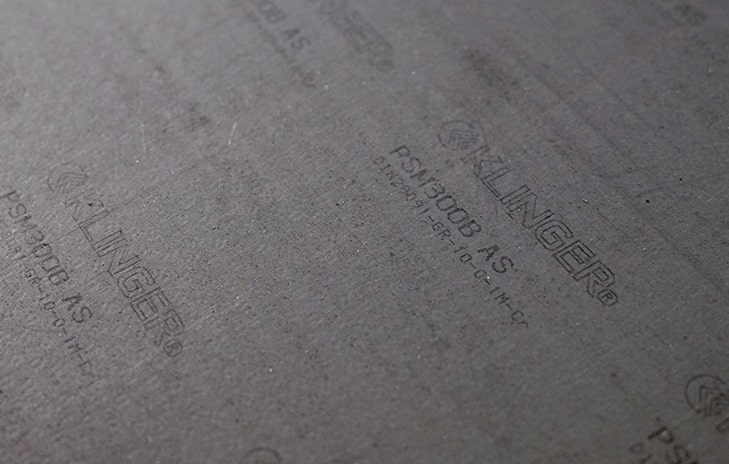

KLINGERSIL PSM / AS

PSM/AS is a graphite material laminated with a 0.1mm thickness tanged stainless steel 316 insert. The insert aids material handling properties and also increases the blow-out resistance. The insert is mechanically bonded to the graphite and does not rely on adhesive. PSM/AS is finished with an anti-stick finish developed to aid removal from the flange even after use at elevated temperatures.

PSM is fire-safe to API 6FB

Application: A wide range of industrial sealing applications including steam, hot water, thermal oils and hydrocarbons.

Temperature: -200 to 460°C

Thickness: 0.8, 1.0, 1.5, 2.0, 3.0 mm

Dimension: 1000 x 1000, 1500 x 1500 mm

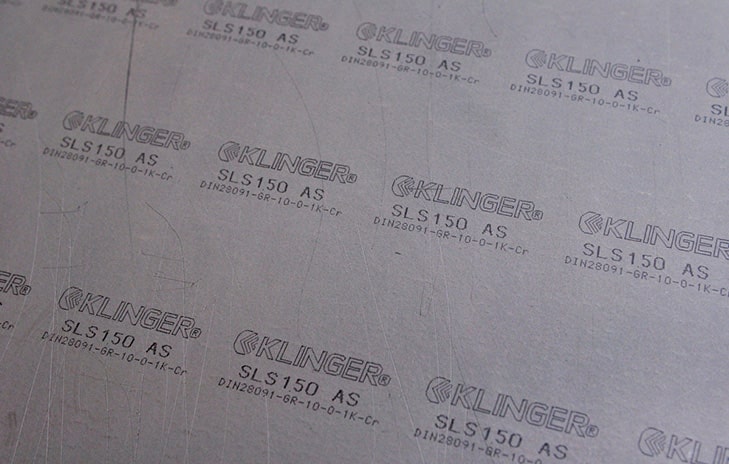

KLINGER SLS / AS

PSM/AS is a graphite material laminated with a 0.1mm thicknSLS/AS is a laminated graphite material with a 0.05mm thickness stainless steel 316 foil insert to aid handling. The insert is bonded to the graphite by means of an adhesive and is easier to cut than PSM/AS. SLS/AS is also finished with an anti-stick coating.

Temperature: -200 to 460°C

Thickness: 0.45, 0.8, 1.0, 1.5, 2.0, 3.0 mm

Dimension: 1000 x 1000 mm

Basis composition: Organic fibersbonded with NBR

KLINGERSIL® C-4430 – offers excellent stress relaxation

Consisting of synthetic fibers bonded with NBR and offering excellent stress relaxation, this gasket material is used in hot water and higher-temperature steam applications. It is resistant to oils, gases, salt solutions, fuels, alcohols, moderate organic and inorganic acids, hydrocarbons, lubricants and refrigerants.

Basis composition: Optimum combination of synthetic fibers bonded with NBR.

Thickness: 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, 3.0 mm

Dimension: 1000 x 1500 mm, 2000 x 1500 mm

Asbestos free beater addition product based on cellulose fibre, bound with protein. Good adaptation properties.

Basis composition: Optimum combination of synthetic fibers bonded with NBR.

Thickness: 0.15 – 3.0mm

Dimension: 1000 x 1500 mm, 2000 x 1500 mm

VALQUA, Black Hyper GF300

Highly heat and chemical resistant Non-asbestos sheet mainly composed of graphite and PTFE that excels in thermal and chemical resistance.

Application: Suitable for industrial units and pipe flanges that are subject to high temperature and used for water, seawater, hot water, steam, air, acids (excluding oxidized acid such as hot, concentrated nitric and sulfuric acids), alkalis, saline water solution, oil, alcohol, aliphatic solvent and its vapor, various gases and liquefied gases.

Temperature: -200 to +300

Thickness: 1.0, 1.5, 2.0, 3.0 mm

VALQUA, 6500 CNAF

Non-asbestos fiber mixed with heat/chemical resisting rubber binder, then rolled and vulcanized

Application: Used as pipe flange and gasket for equipment in various industries.

Temperature: -50 to +183

Thickness: 0.4, 0.5, 0.8, 1.0, 1.2, 1.5, 1.6, 2.0, 3.0 3.2,mm

Dimension: 1270×1270, 1270×3810, 3048x3810mm

VALQUA, Black Super Valqua 6502 – Compressed Non Asbestos Fiber Sheets (CNAF)

High heat and steam resistant Non-asbestos joint sheet that inhibits hardening caused by heat deterioration, by blending highly heat resistant, special rubber binder. Made of heat resistant, artificial inorganic and carbon fibers as well as the minimum amount of organic fibers required. It has excellent sealing characteristics due to its smooth sheet surface and highly dense structure.

Application: Ideal for use as a joint surface gasket for pipe flanges, valve bonnets and covers for various industrial units that require heat resistance in petroleum refining, chemical and shipbuilding industries.

Temperature: -50 to +214

Thickness: 0.5, 0.8, 1.0, 1.5, 2.0, 3.0 mm

Dimension: 1,270×1,270, 1,270×3,810, 2,540×3,810 mm

WHITEHYPER can provide the same performance as No. GF300 and because it has no black material it is good for using when white lines are preferable and has a wide range of other applications.

Application: Joint sections of cover flanges and nozzles and the like for pipe flanges, valve bonnets, towers & tanks, ovens, pressure vessels and heat exchangers used in various factories including power stations, oil refineries, steel plants and shipyards.

Temperature: -200 to +300

Thickness: -200 to +300

About PTTCorp

PTT Corp Sdn. Bhd. is a materials supply, manpower supply, and gasket manufacturing company, offering a wide range of products and services, particularly in the Oil and Gas industries. With over 30 years of experience and state-of-the-art technologies, we provide unrivalled speed of service. We are committed to being the benchmark for quality, excellence, and reliability.

PTTCorp History

Great companies start from humble beginnings, just like PTTCorp in the early 1990s. Formerly known as P & TT Enterprise, we began by undertaking maintenance and minor civil works around Bintulu, Sarawak. In 1996, we expanded into material supply, providing gaskets, filtration products, valves, and other mechanical products.

Dissatisfied with the quality of gaskets received, we decided to design and produce our own gaskets here in Bintulu. Today, we proudly manufacture “tOgap® gaskets” and collaborate closely with renowned gasket makers to ensure the highest quality. We have become a key player supporting industries in Bintulu and beyond.

PTTCorp Health & Safety Policy

Get In Touch!

Address

PTT Corporation Sdn. Bhd. (402360-M)

Lot 1648, Kidurong Industrial Area,

Jln Tanjung Kidurong, 97000 Bintulu,

Sarawak, Malaysia.

Contact

Fax

+6086 255 777