The following are amongst the type of metals we are supplying:

Heat Exchanger Tubes

70/30 Copper Nickel

70/30 Copper Nickel is mainly preferred when the severity of service condition (Cooling water, steam, condensate, temperature, etc.) is such as to virtually rule out all other copper metals. Due to its hardness and to the type of oxide whereby its surfaced is self-protected, 70/30 Copper Nickel has excellent resistance to impingement and erosion – corrosion by suspended solids in sea water flowing at up to 3 – 3.5 m/s. Like all Copper-Nickels, 70/30 Copper Nickel is virtually immune from stress – corrosion cracking. It can be very sensitive to deposit attack and is therefore not recommended for stagnant or slow moving (under 1 – 1.2 m/s) water.

70/30 Sugar Brass Tubes

A Copper Zinc alloy containing Tin and small quantity of Arsenic. This is added as an inhibitor against dezincification. The alloy exhibits a good combination of strength and ductility and is commonly selected whenever excellent cold working properties and relatively low cost are desirable. Application areas of this product are Sugar Industry, Plumbing, Furniture, Hand Pumps, Ammunitions and general engineering.

90/10 Copper Nickel

90/10 Copper Nickel is widely used in sea water. It has very good corrosion resistance to clean or moderately polluted marine or estuary water, even containing dissolved incondensible gases.

This alloy is virtually immune from stress-corrosion cracking. In clean sea water, velocities of up 2.2 – 2.5 m/s are accepted while 4 m/s is the upper limit for clean fresh or slightly saline solutions. To avoid the risk of deposit attack, it is generally recommended to never operate at water velocities below about 0.8 – 1 m/s. 90/10 Copper Nickel can also be used, with appropriately reduced flow velocity, in contact with water containing some sulphides or suspended solids. It is also often selected for its good mechanical properties. both at room and relatively elevated temperatures.

Admiralty Brass

Generally used with fresh, clean waters free from suspended abrasive solids and originating from rivers, lakes and canals. It may also be used with brackish or even saline water. The inhibitive action of arsenic protects Admiralty Brass from dezincification abd the fully annealed alloy can also withstand stress-corrosion cracking. In waters containing less than 2000 ppm dissolved solids its use is allowed at flow rates up to 3 m/s ; in sea waters a maximum speed of 1 m/s is recommended. The presence of tin improves resistance to general corrosion in slightly polluted (sulphurised) water.

Aluminum Brass

Generally used with brackish or sea water. Through its arsenic inhibition, it is virtually immune from dezincification and when fully annealed, also practically free from stress-corrosion cracking. Aluminum Brass is resistant to pitting and even more so to impingement attack : in fresh water, a velocity of up to 3.5 m/s is admitted; it should be reduced to about 2.5 m/s when operating in sea water.

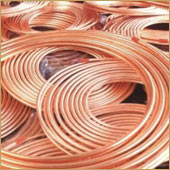

Copper Pan Cake Coils

Copper Pan Cake Coils are commonly known as ARC Coils (Air Conditioning and Refrigeration Coils) are highly acknowledged for long lasting excellent performance, high resistance to wear and tear assures low maintenance cost. Rugged construction makes them perfect to be used in various industries. Other applications are Cooling Towers, Gas Lines and etc.